The Royal Mint has launched a facility designed to extract gold from electronic waste, offering a more sustainable alternative to traditional mining.

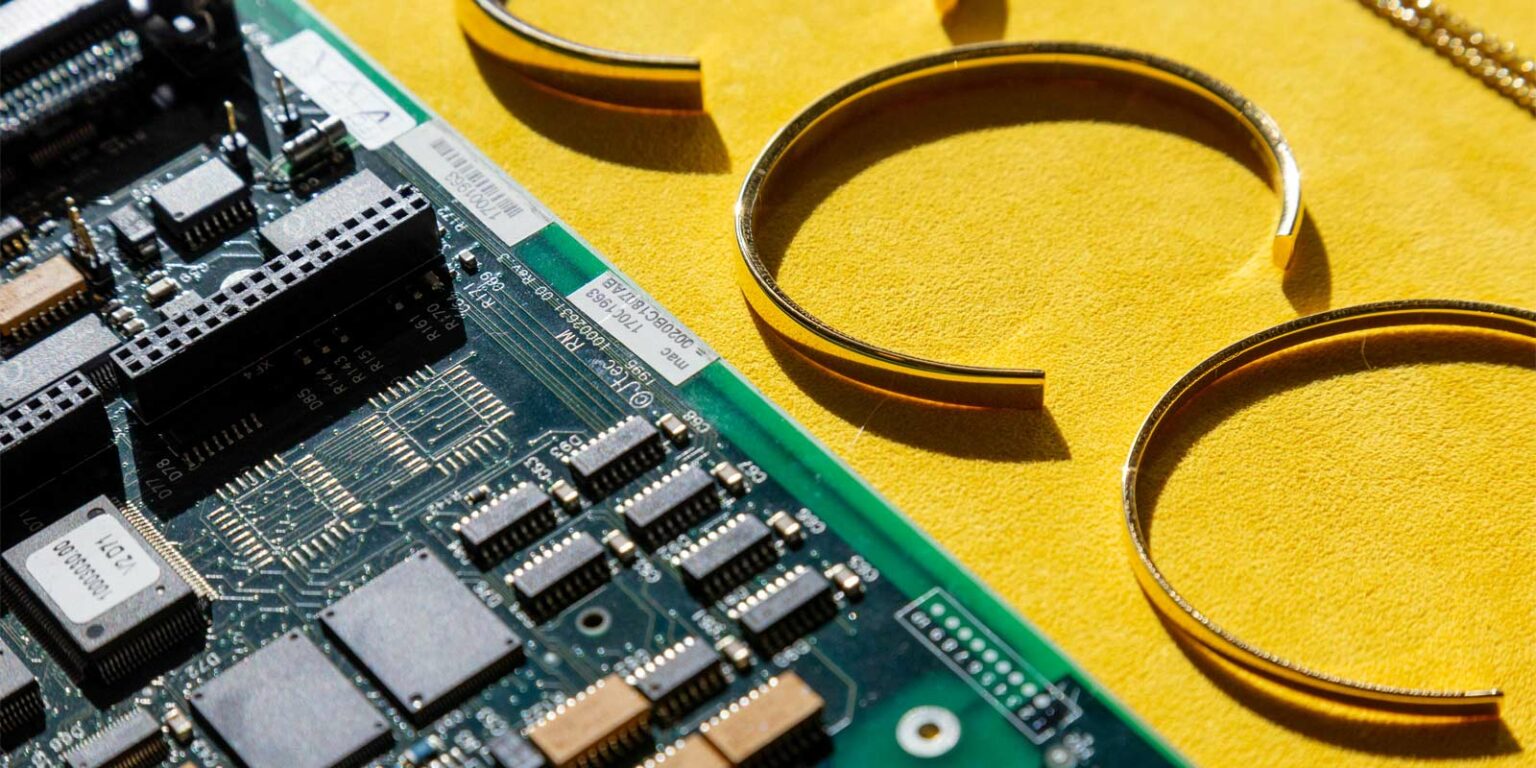

Located in south Wales, the 3,700 square metre factory utilises a patented chemical process developed by Canadian clean tech company Excir to recover gold from printed circuit boards (PCBs) found in everyday electronics.

Technological Innovation

Excir’s technology, which operates at room temperature, allows for a more energy-efficient and cost-effective method of gold recovery.

This process, scaled from laboratory to industrial level for the first time, can process up to 4,000 tonnes of PCBs annually, producing high-quality 999.9 purity gold. The recovered gold is being used in The Royal Mint’s jewellery collection, 886 by The Royal Mint.

Addressing the E-Waste Challenge

The United Nations’ Global E-waste Monitor reports a significant increase in global e-waste, with 62 million tonnes produced in 2022. The Royal Mint’s new factory addresses this issue by recovering valuable resources and appropriately treating other materials for onward processing.

Strategic Vision and Industry Impact

Anne Jessopp, Chief Executive at The Royal Mint, emphasised the importance of this development:

“The Royal Mint is transforming for the future, and the opening of our Precious Metals Recovery factory marks a pivotal step in our journey.”

This initiative is part of The Royal Mint’s strategy to preserve precious metals while maintaining its craftsmanship by creating new jobs and reskilling opportunities for employees.

Industry Standards and Sustainable Practices

The Royal Mint is working with major industry bodies to establish the first ISO standard for recycled gold, providing clarity for the industry and stakeholders. Sean Millard, Chief Growth Officer at The Royal Mint, highlighted the factory’s role in their sustainability efforts:

“The factory underpins our commitment to using sustainable precious metals and providing a new source of high quality, recovered gold.”

Future Prospects

The decline in global cash usage has driven The Royal Mint to innovate and diversify its operations.

Earlier this year, the company announced the closure of its Overseas Currency division, with all 230 staff offered roles in new business areas, including the Precious Metals Recovery factory. This move is intended to sustain manufacturing roles and ensure the long-term viability of The Royal Mint.

Industry Implications

The opening of the Precious Metals Recovery factory represents a significant step towards more sustainable practices in the jewellery industry. Using new technology to recycle e-waste, The Royal Mint is contributing to environmental responsibility and resource conservation in the production of precious metals.

For further details on the Precious Metals Recovery factory, visit Precious Metals Recovery on the Royal Mint website.